Fiber Cement Board Market: A Quiet Revolution in Passive Fireproofing and Modular Construction Systems

Fiber cement boards are evolving from cladding materials to key components in fireproofing and modular systems, driving growth in specialty construction sectors

High-performance fiber cement boards are gaining traction in fire-rated and prefab systems, as stricter safety codes and modular trends reshape global construction priorities.”

NEWARK, DE, UNITED STATES, June 3, 2025 /EINPresswire.com/ -- While fiber cement boards are widely known for their application in façade cladding, roofing, and wall partitions, a less discussed yet strategically significant development is their role in passive fire protection systems and modular prefabricated structures. As building safety codes tighten globally and modular construction gains momentum, fiber cement boards are no longer just a building material—they are evolving into an essential safety and performance component in the next generation of architecture.— Nikhil Kaitwade, Associate Vice President at Future Market Insights

This shift is especially pronounced in high-density urban environments and industrial zones where fire-resistance, thermal insulation, and structural reliability converge. High-performance fiber cement boards—engineered with enhanced fire ratings, moisture resistance, and mechanical integrity—are emerging as foundational elements in prefabricated wall panels, fire-rated ducting systems, and blast-proof modular cabins.

𝐅𝐨𝐫 𝐌𝐨𝐫𝐞 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 𝐨𝐧 𝐭𝐡𝐢𝐬 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲, 𝐆𝐞𝐭 𝐚 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭! https://www.futuremarketinsights.com/reports/sample/rep-gb-10369

𝐁𝐞𝐲𝐨𝐧𝐝 𝐂𝐥𝐚𝐝𝐝𝐢𝐧𝐠: 𝐅𝐢𝐛𝐞𝐫 𝐂𝐞𝐦𝐞𝐧𝐭 𝐚𝐬 𝐚 𝐅𝐢𝐫𝐞-𝐑𝐞𝐬𝐢𝐬𝐭𝐚𝐧𝐭 𝐄𝐧𝐯𝐞𝐥𝐨𝐩𝐞

Fiber cement board is a composite material made of cement reinforced with cellulose fibers and other additives. While its traditional appeal lies in its resistance to rot, mold, and termites, modern formulations now exhibit superior fire resistance ratings (FRRs) of up to 2 hours or more under ASTM E119 or EN 13501-2 standards.

This level of performance positions fiber cement boards as a passive fire protection solution in hospitals, schools, server rooms, and high-rise residential buildings. In these contexts, the material acts as a barrier that slows the spread of fire, allowing more time for evacuation and emergency response.

One notable case study comes from Singapore’s public housing sector, where the Building and Construction Authority (BCA) endorsed fiber cement boards as the material of choice for partition systems in fire-rated corridors and stairwells. The material’s ability to maintain structural integrity under high heat and moisture makes it a safer alternative to traditional gypsum boards or plywood in such critical applications.

𝐌𝐨𝐝𝐮𝐥𝐚𝐫 𝐚𝐧𝐝 𝐏𝐫𝐞𝐟𝐚𝐛 𝐂𝐨𝐧𝐬𝐭𝐫𝐮𝐜𝐭𝐢𝐨𝐧: 𝐀 𝐅𝐢𝐛𝐞𝐫 𝐂𝐞𝐦𝐞𝐧𝐭 𝐂𝐨𝐫𝐞

Another emerging trend is the integration of fiber cement boards into modular construction systems, where prefabricated wall and floor panels are built offsite and assembled rapidly on-site. This method, which is transforming commercial and residential construction, relies heavily on materials that are dimensionally stable, durable, and lightweight—traits that align perfectly with engineered fiber cement boards.

In regions like Scandinavia, Japan, and the UAE, modular schools, hospitals, and temporary worker accommodations now feature internal and external walls clad with multi-layer fiber cement panels. These boards act as both structural and aesthetic elements, reducing the need for finishing layers while meeting acoustic and thermal performance benchmarks.

A key advantage here is fiber cement’s low coefficient of thermal expansion and excellent load-distribution properties, which help prevent warping and cracking during transport and installation. Additionally, its inherent fire resistance means that builders can meet local codes without having to add expensive supplementary fireproofing systems.

𝐓𝐨 𝐆𝐚𝐢𝐧 𝐌𝐨𝐫𝐞 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 𝐚𝐛𝐨𝐮𝐭 𝐭𝐡𝐢𝐬 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡, 𝐕𝐢𝐬𝐢𝐭! https://www.futuremarketinsights.com/reports/fiber-cement-board-market

𝐇𝐢𝐠𝐡-𝐃𝐞𝐧𝐬𝐢𝐭𝐲 𝐀𝐩𝐩𝐥𝐢𝐜𝐚𝐭𝐢𝐨𝐧𝐬: 𝐅𝐫𝐨𝐦 𝐎𝐢𝐥 𝐑𝐢𝐠𝐬 𝐭𝐨 𝐃𝐚𝐭𝐚 𝐂𝐞𝐧𝐭𝐞𝐫𝐬

In industrial sectors such as oil & gas, chemical processing, and data centers, fire safety and structural resilience are paramount. High-density fiber cement boards, often exceeding 1200 kg/m³ in density, are increasingly used as lining materials in blast-resistant enclosures, HVAC ducts, and server containment structures.

These boards can resist both high temperatures and mechanical impact, making them suitable for critical infrastructure environments that must maintain function even in emergencies. In fact, several refineries in the Middle East have adopted thick-layer fiber cement panels in explosion-resistant buildings due to their superior spalling resistance compared to concrete or steel linings.

Furthermore, the boards’ resistance to UV degradation and chemical corrosion adds to their appeal in harsh operational climates, further expanding the scope of this traditionally architectural product.

𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥 𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧 𝐚𝐧𝐝 𝐒𝐮𝐬𝐭𝐚𝐢𝐧𝐚𝐛𝐢𝐥𝐢𝐭𝐲 𝐂𝐫𝐨𝐬𝐬𝐫𝐨𝐚𝐝𝐬

Despite their robustness, fiber cement boards are facing pressure to align with green building standards and circular economy goals. The Portland cement content, while essential for structural properties, is associated with high carbon emissions. Manufacturers are responding by developing low-cement and geopolymer-based fiber cement boards, which reduce the carbon footprint by up to 30%.

Some producers have begun incorporating recycled cellulose fibers or industrial ash to create eco-fiber cement variants, which not only offer comparable performance but also appeal to LEED and BREEAM certification requirements.

In 2024, a Netherlands-based startup launched a fully carbon-neutral fiber cement panel made from bio-ash, recycled fiber pulp, and synthetic binders—an innovation now being tested in green-certified housing developments across northern Europe.

𝐆𝐞𝐧𝐞𝐫𝐚𝐥 & 𝐀𝐝𝐯𝐚𝐧𝐜𝐞𝐝 𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥𝐬 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬: https://www.futuremarketinsights.com/industry-analysis/general-and-advanced-materials

𝐌𝐚𝐫𝐤𝐞𝐭 𝐒𝐞𝐠𝐦𝐞𝐧𝐭𝐚𝐭𝐢𝐨𝐧 𝐚𝐧𝐝 𝐅𝐮𝐭𝐮𝐫𝐞 𝐓𝐫𝐚𝐣𝐞𝐜𝐭𝐨𝐫𝐲

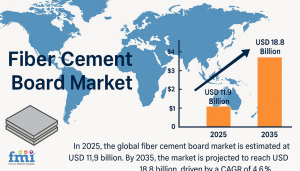

According to Future Market Insights, in 2025, the global fiber cement board market is estimated at USD 11.9 billion. By 2035, the market is projected to reach USD 18.8 billion, driven by a CAGR of 4.6%. This shift is being driven by stricter building codes, rising insurance standards, and the overall pivot toward offsite construction.

Asia-Pacific continues to lead in volume due to massive housing and infrastructure demands, but North America and Europe are setting the pace in premium-grade and code-compliant product variants. As urban fire safety concerns grow, even emerging markets are revising their standards, pushing architects and engineers toward non-combustible materials like fiber cement.

𝐀 𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥 𝐑𝐞𝐢𝐧𝐯𝐞𝐧𝐭𝐞𝐝 𝐟𝐨𝐫 𝐭𝐡𝐞 𝐀𝐠𝐞 𝐨𝐟 𝐑𝐞𝐬𝐢𝐥𝐢𝐞𝐧𝐜𝐞

The fiber cement board market is undergoing a transformation from commodity-based exterior cladding to mission-critical building system component. As global demands shift toward safer, faster, and more sustainable construction, fiber cement boards are proving their versatility beyond aesthetics—playing crucial roles in fire-rated assemblies, high-performance prefab structures, and industrial resilience systems.

With continued material innovation and regulatory alignment, fiber cement boards are well positioned not just as a substitute for gypsum or wood, but as a cornerstone in the built environment’s response to climate, safety, and speed.

𝐊𝐞𝐲 𝐒𝐞𝐠𝐦𝐞𝐧𝐭𝐚𝐭𝐢𝐨𝐧

By Product Type:

The Product Type segment is further categorized into Siding Boards, Flooring Boards, Roofing Boards, Ceiling Boards, Partition Boards, Decorative Boards and Insulation Boards.

By Application:

The Application segment is classified into Residential Construction, Commercial Construction, Industrial Construction, Agricultural Buildings, Interior Applications, Walls, Ceilings, Partitions and Exterior Applications.

By Thickness Type:

The End Use segment is classified into Below 6 mm, 6 mm to 12 mm and Above 12 mm.

By Region:

Regions considered in the study include North America, Latin America, Western Europe, Eastern Europe, East Asia, South Asia & Pacific, and the Middle East and Africa.

𝐑𝐞𝐥𝐚𝐭𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭𝐬:

Fiber Cement Market: https://www.futuremarketinsights.com/reports/fiber-cement-market

Glass Fiber Reinforced Plastic (GFRP) Composites Market: https://www.futuremarketinsights.com/reports/global-glass-fiber-reinforced-plastic-composites-market

Potassium Formate Market: https://www.futuremarketinsights.com/reports/potassium-formate-market

Compressor Oil Market: https://www.futuremarketinsights.com/reports/compressor-oil-market

Conductive Fiber Market: https://www.futuremarketinsights.com/reports/conductive-fibers-market

𝐀𝐛𝐨𝐮𝐭 𝐅𝐮𝐭𝐮𝐫𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 (𝐅𝐌𝐈)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Ankush Nikam

Future Market Insights Global & Consulting Pvt. Ltd.

+ +91 90966 84197

email us here

Visit us on social media:

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.